Business processes, a set of activities that accomplish a specific organizational goal, are everywhere throughout organizations. In this blog, I highlight four key business processes present in chemicals companies and their purposes. I also share some examples of chemicals companies that have unlocked business value within and across these processes as part of digital transformation initiatives.

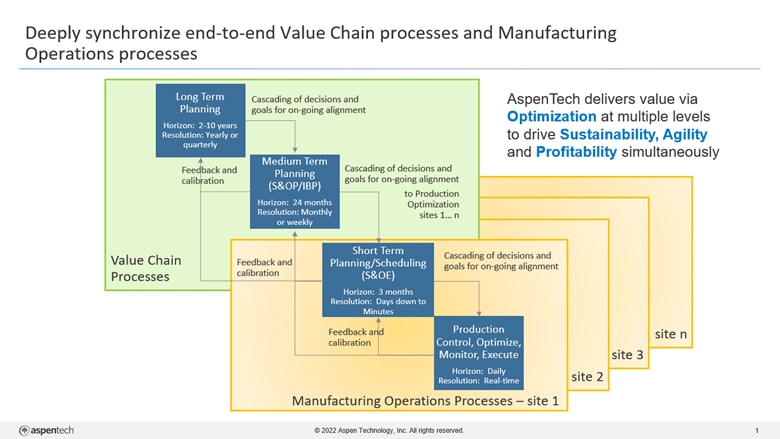

Organizations should pay attention to business processes because they determine how well they can move toward achieving its sustainability, agility and profitability goals. The better a company’s processes, the more effective the business. More importantly, an organization’s business processes can become a competitive advantage for chemicals’ producers, especially if you deeply synchronize key value chain processes with manufacturing operations processes. This is critically important in the context of digital transformation initiatives.

|

|

| Figure 1: Framework illustrating the four key business processes (blue boxes) spanning value chain and manufacturing operations |

Long-term planning processes – what is the purpose?

Every manufacturing company, no matter its size, does some form of long-term planning. The planning at this level typically looks two-to-10 years into the future. Long-term planning is often closely related to capital budgeting activities, a process by which a company determines the value of potential investment projects and involves analyzing potential investment projects to understand their projected operational and financial benefits. Examples of such long-term planning studies include: CapEx and/or OpEx economic investments studies, sustainability and emissions reduction studies, manufacturing footprint studies, etc.

During our Optimize 2019 conference, Momentive Performance Materials gave a presentation about how they used Aspen Supply Chain Planner™ (SCP) for strategic supply chain network analysis and redesign studies. In a recent case study, Repsol Chemicals stated that the solution “enables support for strategic studies, such as the ability to analyze decisions to buy, sell or build production lines, depots and other assets.” AspenTech customers deeply value our mathematical optimization capabilities, which is typically set to maximize profits, across the end-to-end value chain, over the planning time horizon.

From a sustainability standpoint, a chemicals producer has started using their Aspen SCP solution to make progress in addressing the Dual Challenge – considering profitability and sustainability goals holistically. This customer incorporated Scopes 1, 2 and 3 related emissions data into the solution. For Scopes 1 and 2 emissions data, the customer gathered this from internal systems. For Scope 3, the customer worked with their suppliers and logistics providers to come up with the data and emissions factors. The company is now using the solution to evaluate potential CapEx/OpEx investment projects related to sustainability to plot an efficient path to achieving their near and long-term net zero goals. For example, they analyzed a proposed CapEx investment related to a potential solar electricity project at a manufacturing site, its impact on their enterprise-wide profit and loss (P&L), as well as projected reduced emissions forecasts over a 10-year planning horizon.

Medium-term planning processes – what is the purpose?

Many companies have a name for this process: Sales and Operations Planning (S&OP) or Integrated Business Planning (IBP). The planning done at this level typically looks 24 months into the future across the entire supply chain and provides value by ensuring that the company is working towards its strategic P&L goals — balancing end-to-end supply & demand and maximizing profitability.

During the Optimize 2021 conference, SABIC presented how they use Aspen Supply Chain Management as part of their monthly S&OP process to optimize their Engineering Thermoplastics and Specialties business units. Similarly, Perstorp shared with Forbes how they are using the solution as part of their S&OP/IBP processes to evaluate supply and demand scenarios based on marginal economic contribution impacts.

From a sustainability standpoint, we are working with European companies; demonstrating how to augment existing AspenTech supply chain solutions with respect to ISCC Plus or ISCC EU mass balance chain of custody approaches for holistically planning their bio feedstocks alongside other materials across their value chain.

Short-term planning and scheduling processes – what is the purpose?

Short-term planning is as ubiquitous to companies as both medium and long-term planning. This is, however, typically a daily process and is often referred to as Sales and Operations Execution (S&OE) which typically looks up to three months into the future at a high level of resolution. An S&OE process provides value by enabling supply chain and manufacturing operations team members to respond and manage the inevitable daily supply and demand disruptions that occur.

In a 2021 customer panel roundtable discussion, Bakelite Synthetics shared that, thanks to Aspen Plant Scheduler™, their organization has “an incredible ability to look beyond… and see 90 days into the future.” Translation: they can see inventory, capacity utilization and demand developments and trends at the required level of accuracy and granularity. Dow Chemicals was also featured in a webinar in which they explained how Aspen Plant Scheduler helps them better schedule in their Coatings and Polyurethanes businesses.

Always striving to consider sustainability, we helped one of our European customers in the specialty chemicals industry that has a regulatory requirement on Sulphur Dioxide (SO2) emission limits. This customer has the ability, within their AspenTech Plant Scheduler solution, to calculate and track instantaneous SO2 output which can then be used to observe the scheduled production against the limit. The customer now gets alerts and their schedulers can adjust the production schedule to reposition certain products to smooth the emissions and stay within the regulatory limits.

Production optimization, monitoring, and execution processes – What is the purpose?

The synchronization of key data, models, business processes and people are vital to ensure that operations execution team members stay aligned. This all starts with realistic daily or weekly production goals, derived from the short-term planning and scheduling process just covered. Many companies, such as Shell Catalysts and Hexion, now enable daily alignment across their supply chain and manufacturing operations teams via a digital manufacturing collaborative hub that we offer called Aspen Schedule Explorer™.

Digital Transformation: Deep synchronization and alignment across processes unlocks trapped value

The overarching goal is to ensure that all these processes remain aligned so that decisions being made in the higher-level planning processes can cascade down toward day-to-day execution. It is equally important that all the enabling supply chain and manufacturing operations digital solutions used in these business processes remain appropriately synchronized. Deep synchronization across value chain and manufacturing operation processes is a critical element to enable chemicals companies to digitally transform and reach new levels of customer centricity, sustainability, agility, and profitability.

Repsol Chemicals won a prestigious “2022 Top Supply Chain Projects Award” for their Control Tower project. It is a great example of a chemicals digital transformation project spanning all the business processes covered in this blog, as well as spanning processes across business units (upstream olefins cracker planning process along with downstream polymers S&OP/IBP process).

Another chemicals digital transformation project in progress involves a polymers manufacturer that AspenTech is helping to enable a deeper level of synchronization at one of its key manufacturing sites. The project scope includes enabling synergies spanning short-term planning and scheduling processes (Aspen Plant Scheduler™), digital manufacturing collaboration processes (Aspen Schedule Explorer™), grade-to-grade transition management (Aspen Transition Management™ and Aspen Production Record Manager™), and advanced process control (Aspen DMC3™). The project is a key digital transformation initiative that will help the manufacturer unlock new levels of commercial and manufacturing operations agility.

.png?la=en&h=250&w=975&hash=DDCDF4484AABDCEDCACED3F142FA8F37)

Leave A Comment