Asset Performance Management

Combine market-leading Industrial AI with first principles and 40+ years of domain expertise to achieve unparalleled operational reliability.

Cut through the hype. Unlike standard AI that relies solely on failure history, AspenTech APM understands the process conditions that impact future asset performance and product quality.

The Enterprise Standard for Reliability

Predict early, prescribe quickly and accurately with a scalable APM solution that minimizes risk and maintenance costs while improving product yield and quality. Deliver continuous operational improvement across your organization .

-

Rapidly scale your reliability strategy with Industrial AI that grows seamlessly from foundational asset health monitoring to advanced prediction.

5 Ways Aspen Mtell Asset Templates Accelerate Time-to-Value

The asset templates within Aspen Mtell enable companies to easily and quickly scale and deploy prescriptive maintenance solutions. Using pre-populated templates, you can set up sensor groups and quick...

Interactive Infographic

Delivering on the Promise of Prescriptive Maintenance

Leading asset-intensive companies are using prescriptive maintenance—powered by AI and machine learning—to unlock the value and productivity lying uncaptured in assets. Using a scalable, easy to imple...

White Paper

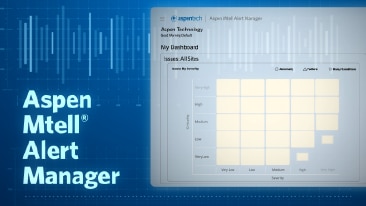

Streamlining Maintenance Workflows with Aspen Mtell Alert Manager

Plant engineers often face disjointed workflows and a lack of critical information to make quick, informed decisions when troubleshooting equipment issues. Now, with the Alert Manager functionality wi...

Video-

Improve quality, yield and waste reduction through process and product degradation prediction and optimization.

Improve Process Efficiency and Product Quality with Aspen ProMV®

For chemical and petrochemical producers, reducing emissions and minimizing disruptions to process requires analyzing and monitoring vast amounts of disparate process data. Learn how Petrocuyo, Braske...

Video

Top Diesel and Naphtha Producer Uses Product and Process Quality Analytics to Reduce Flaring, Emissions

ORYX GTL Limited is a gas-to-liquids (GTL) diesel and naphtha producer located in Doha, Qatar. The company is committed to reducing its carbon production through the minimization of flaring. By implem...

Case Study

Increase Process Efficiency and Product Quality with Real-Time Data Analytics

Process industries like bulk chemicals, specialty chemicals and pharmaceuticals strive to optimize production processes with existing resources and data to remain competitive and profitable. By implem...

Video-

Maximize performance and evaluate plantwide risk/reward of CAPEX, OPEX and operational mitigation decisions.

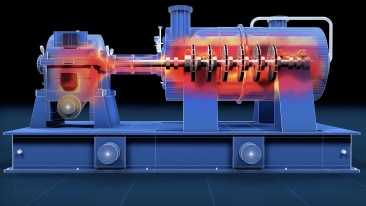

Improve Asset Reliability with Aspen Mtell and Aspen Fidelis

Machine learning technology can now predict equipment failures weeks in advance. But how do you decide when and how to perform the repair to maximize productivity and minimize risk? Learn how Aspen Mt...

Video.png?sc_lang=en&la=en&h=206&w=366&hash=7391455D51F0784C315C7D7C368BD130)

Aspen Fidelis™: Empowering Confident Decision Making

See how Aspen Fidelis enables any engineer in any department to identify the cause of lost operational availability and justify important decisions.

VideoProven Value Measured in Millions