Aspen Mtell® is a predictive and prescriptive maintenance solution that can provide early warnings of potential failures using a series of agents to monitor your equipment 24 hours a day. These can range from rules-based condition monitoring agents to machine learning agents that provide the earliest failure warnings. Furthermore, Aspen Mtell monitors groups of sensors not only on the equipment, but upstream and downstream of the equipment. This allows monitoring of process conditions that can lead to failure, providing the earliest warnings to avoid downtime.

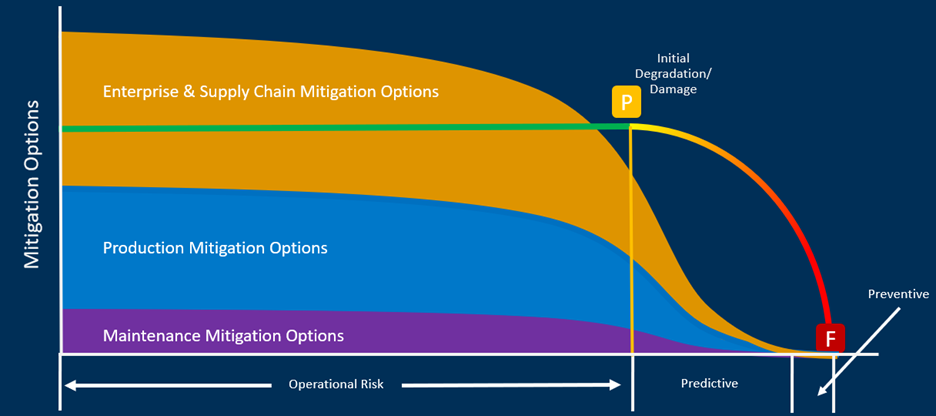

By using historized time series data, ranging from minute to hourly, Aspen Mtell’s machine learning can identify multivariate sensor data and provide alerts indicating possible or early-stage failure. The goal of this early alerting is to allow maintenance and operations planners to make the right choices for how and when to best address issues. This results in increased mitigation options and insight into the impact on production requirements.

Figure 1: Increased mitigation options with early predictive analytics

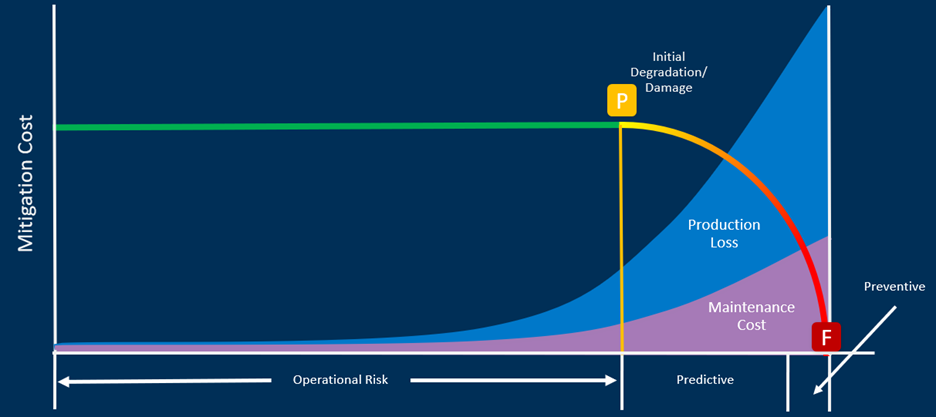

In addition, the earlier the alert is received, the more the financial impact of the mitigation is reduced. Aspen Mtell accomplishes this in several ways. First, it enables process change that eliminates the conditions that could lead to failure. Additionally, it gives maintenance planners time to develop the most cost-effective way of reducing economic impact without having to “hot shot” spare parts. It also enables them to utilize repair crews for addressing this risk and possibly other required maintenance needs, and it eliminates overtime costs for maintenance personnel. The biggest impact Aspen Mtell delivers is avoiding having to take equipment out of service and instead, scheduling this time to coincide with an upcoming planned outage, eliminating unplanned operational downtime.

Figure 2: Decreased mitigation costs with early predictive analytics

Often people try to utilize Aspen Mtell and predictive analytics for alarming purposes. Alarming should be utilized for letting customers know when things are changing very rapidly, and when immediate action is required to prevent a catastrophic breakdown of equipment or process conditions. There are typically several systems in place, such as a DCS, that notify personnel when an issue is about to happen and often provides the immediate remediation for the alarm.

Machine learning and digital solutions allow everyone, from operators to the boardroom, to see the state of equipment at-a-glance. When recently implemented at a multinational energy company, Aspen Mtell was utilized to predict failure on a hydrogen compressor with 35 days lead-time. The advanced alerting avoided an emergency shutdown and allowed the customer to meet its scheduled production goals. Overall implementation of Aspen Mtell at various sites has resulted in 30% savings in maintenance costs per year for the customer.

With its AI-driven agents, Aspen Mtell offers a comprehensive solution that not only enhances equipment monitoring but also empowers stakeholders at all levels; ultimately driving efficiency, reliability, and cost-effectiveness.

.png?la=en&h=250&w=975&hash=FAE19F1D36E812D036B7F3D84F150E2B)

.png?la=en&h=415&w=675&hash=A4B88DE3ACD2F024184649320D8E2335)

.png?la=en&h=415&w=675&hash=52BF2B7152277BCB699F6B760EBCEF0D)

Leave A Comment