Accelerate Innovation for Carbon Capture, Utilization and Storage (CCUS)

Improve economics and reduce risks in CCUS to scale and commercialize CO2 capture technologies (for point source and direct air capture), speed up execution of projects and optimize across the complete value chain.

Address Challenges to Drive Low-Risk CCUS Solutions at Scale

Leverage the leading digital solutions for process simulation, risk and reliability analysis, optioneering and subsurface analytical, modeling and simulation to ensure economics and safety across the carbon capture value chain.

- Reduce 5-20% CAPEX and 15-30% OPEX

- Shorten project time by 20%

- Support permit applications and cut permitting time by 50%

- Select storage locations and reduce injection risk

- Demonstrate permanent geological storage

- Scale up CO2 to chemicals utilization technologies

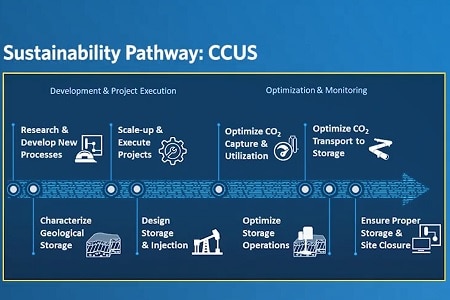

Sustainability Pathway: Carbon Capture, Utilization and Storage (CCUS)

Accelerate innovation to scale carbon capture, utilization and storage with AspenTech digital solutions:

- Improve economics and scale-up faster

- Identify options to reduce project lifecycle cost

- Make informed decisions and justify investment

- Ensure confidence in low-risk, long-term storage

Impact Key Business Processes to Accelerate Innovation for CCUS

Carbon Capture Design | Carbon Capture Operations | Carbon Storage | Carbon Utilization

.png?la=en&h=415&w=675&hash=092ECA8EB141EE4E3AAA083EBE5CB26D)

.png?la=en&h=415&w=675&hash=F924FF47DF9DA6DBF8CC8E9CAA3011D7)

.png?la=en&h=415&w=675&hash=9FBAC1DC24F740445965F111A8507D86)