I am proud to announce that AspenTech has been honored with a Green Supply Chain Award from Supply and Demand Chain Executives – for a second year in a row. This award recognizes companies that are making sustainability a core part of their supply chain strategy, as well as those working to achieve measurable goals within their operations.

Last year, AspenTech won a Green Supply Chain Award for helping enable FP Corporation to provide stable and responsive food distribution in an efficient, sustainable, environmentally friendly way. The company is Japan’s largest producer of food tray containers (with over 12,000 SKUs) used by supermarkets and convenience stores. During our OPTIMIZE 2021 conference, FP Corporation’s President, Mr. Morimasa Sato, stated in his keynote presentation, “I believe that our supply chain, including AspenTech’s SCM system, is a great strength.”

This year, AspenTech received a Green Supply Chain Award for providing new solutions to enable customers to make progress more quickly toward sustainability goals. Numerous sustainability sample models – including supply chain planning and scheduling, emissions reduction, and hydrogen supply chain design – help customers jumpstart their sustainability projects to meet sustainability goals.

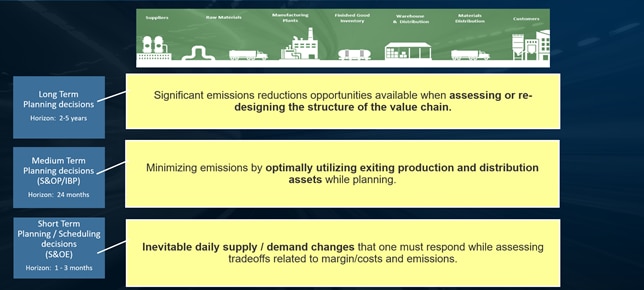

Incorporating sustainability factors into customers’ existing AspenTech supply chain planning and scheduling models allows for the expansion of standard plan and schedule analysis criteria (demand adherence, distribution modes and activities, allocation of production to plants, production goals, etc.) – to observe and answer a host of new questions:

- How are CO2 emissions constraints designated? Governmental restrictions? Geographical considerations – local, regional or global? How do production and distribution decisions change as emissions are constrained at different levels?

- How do we remain efficient and profitable while minimizing the impact of CO2 emissions? Do we shift production to more costly sites to achieve CO2 emissions reduction goals?

- How do energy sources impact CO2 emissions and what control do we have over the emission consequences of our decisions?

Sustainability – Supply chain decisions impact Scope 1, 2 and 3 emissions

Supply Chain Sustainability Trends

In my previous blog, I shared highlights from our recent AspenTech Supply Chain Management customer roundtable and how the AspenTech solution has helped customers respond to an unprecedented VUCA supply chain environment. I wanted to take this opportunity to share highlights from the sustainability portion of the roundtable discussion, which included supply chain sustainability trends that AspenTech is seeing – especially in Europe – and how sustainability factors can be incorporated into customers’ AspenTech planning and scheduling models.

Luigi Aleotti, European Solution Consulting Director at Aspen Technology, began the sustainability portion of the conversation by summarizing his recent involvements in several customer improvement programs focused on both margin optimization and CO2 emissions reduction. He explained how AspenTech is deeply involved in multiple engagements around production optimization and energy reduction – mainly focused on Scope 1 and 2 emissions. He shared insights on how some customers are looking for CO2 modelling in feedstock and raw material selection processes, and how AspenTech solutions can help process manufacturing companies track their planned emissions versus their actual emissions in near-real time. He also explained how some customers are working towards the goal of being able to understand the marginal economics and impact of CO2 emissions on corporate financials as part of their supply chain planning processes.

Incorporating Sustainability Factors to AspenTech Supply Chain Models

AspenTech Senior Principal Supply Chain Solution Consultant, Jack Hitchens, explained how AspenTech had modeled CO2 emissions and the purchase of carbon offset credits in a supply chain planning optimization model over a decade ago for a customer in a relatively high emission industry. The customer included CO2 emissions within their supply chain planning model, together with the regional limit and carbon credit purchases where planned emissions exceeded the limit.

Jack explained how it is possible to model emissions related to production and distribution activities, and in some cases from the use of different kinds of raw materials with different carbon loads that can be represented by different production operations. One key question is whether a manufacturing company has the flexibility to change their supply chain planning decisions in a way that will influence emissions. If the answer is yes, then there is a clear benefit for including emissions generation within planning models. If the answer is no, then you can still model emissions for its effect on a company’s financial margin and for reporting planned emission levels across the model time horizon. A manufacturing company may for instance want to run strategic economic what-if investment scenarios to understand what the economic effect is of cutting emission by different amounts.

Finally, Jack explained how one of our European customers in the specialty chemicals industry has a regulatory requirement on Sulphur Dioxide (SO2) emission limits. SO2 is a by-product of production of different feedstocks; so different products result in different amounts of SO2 emissions. This customer has the ability within their AspenTech SCM scheduling solution to calculate and track instantaneous SO2 output, which can be used to observe the scheduled production against the limit. Within the AspenTech SCM solution, the customer sees an alert and their schedulers can adjust the production schedule to reposition certain products to smooth the emissions and stay within the regulatory limits.

Working with Customers to Find and Develop New Solutions for Sustainability

We're making progress, but there is still much more work to be done to address the triple-bottom line and to develop successful businesses that address environmental and social concerns. As previously mentioned, AspenTech recently released more than 50 sustainability sample models for our customers to help them accelerate their sustainability initiatives. Using these models, customers can identify how to reduce emissions across the entire supply chain; reduce usage of energy, water and feedstocks; transition to new energy sources like biofuels and hydrogen; and enable the circular economy through processes such as plastics recycling and waste-to-chemicals. As we move forward into 2022, we will continue to help companies accelerate the innovation they need to lower emissions and waste, and to develop future technology solutions.

Leave A Comment