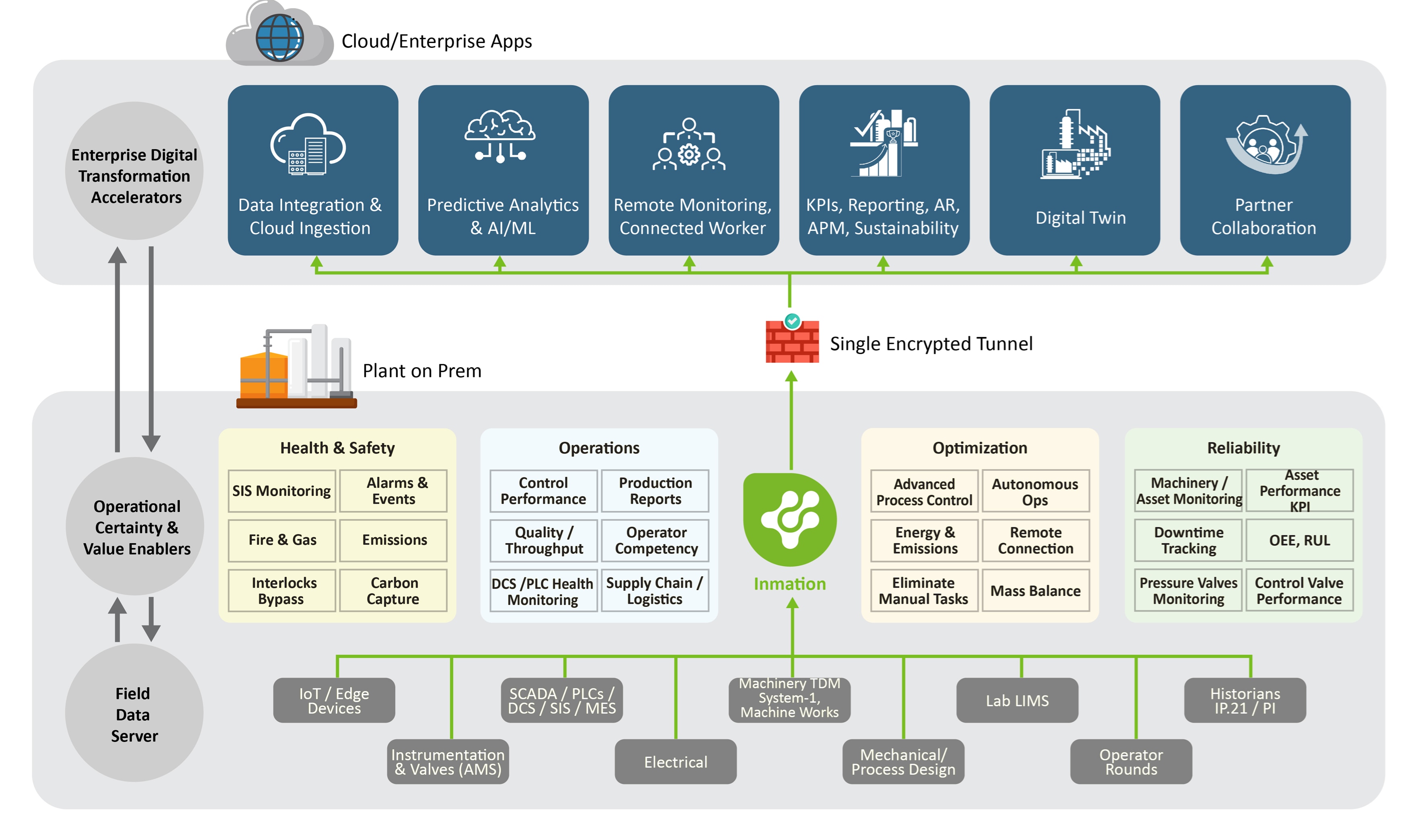

AspenTech Inmation™ — The Industrial Data Fabric

Data integration and management platform connecting shop floor operations to enterprise and cloud systems, reshaping OT environments and providing aggregated, contextualized data for digital transformation initiatives.

“At TotalEnergies, digital technology is a key enabler of our transformation toward a more sustainable and efficient energy future. Our collaboration with Emerson demonstrates how advanced technologies such as AspenTech Inmation, help us to optimize operations, reduce emissions, and generate long-term value. This collaboration is a sign of our intention to turn data and digital tech into the hallmarks of our facilities’ industrial excellence.”

— Namita Shah, President of OneTech at TotalEnergies

BASF leveraged AspenTech Inmation to connect disparate industrial data sources across global operations, enabling real-time analytics, improved process efficiency and enhanced customer value through improved manufacturing intelligence and data management.

The scalable platform integrates legacy systems and standardizes data, providing robust visualization, secure data transport and enterprise-wide connectivity for smarter manufacturing.

Data Contextualization at Scale

Enables AI for Industrials

Low TCO and High Resiliency

Native Cybersecurity and Regulatory Functionality

Liberate OT Data

From device to decision maker, connect your operational technology data into one platform that drives digital transformation initiatives and uncovers actionable insights.

- Aggregate and contextualize enterprise OT data seamlessly in one central location

- Make relevant information visible and accessible to all stakeholders

- Optimize efficiency and decision making through analytics and visualization

- Fuel digital transformation technology with the data needed to perform at scale

Manage Enterprise-Wide Data Connectivity

Connect to a wide range of different servers, systems, interfaces, endpoints and data sources.

- OPC: DA, HDA, A&E

- OPC UA: Realtime, History, A+C

- ODBC Datasource

- Files: TXT, CSV, JSON, XML, XLXS

- MQTT

- Kafka

- HTTP

- Generic TCP

- Modbus

- PLC/Ethernet/IP

- OSI PI/PI AF

- Honeywell PHD

- Siemens Simatic Batch

- Mettler Toledo

LabX

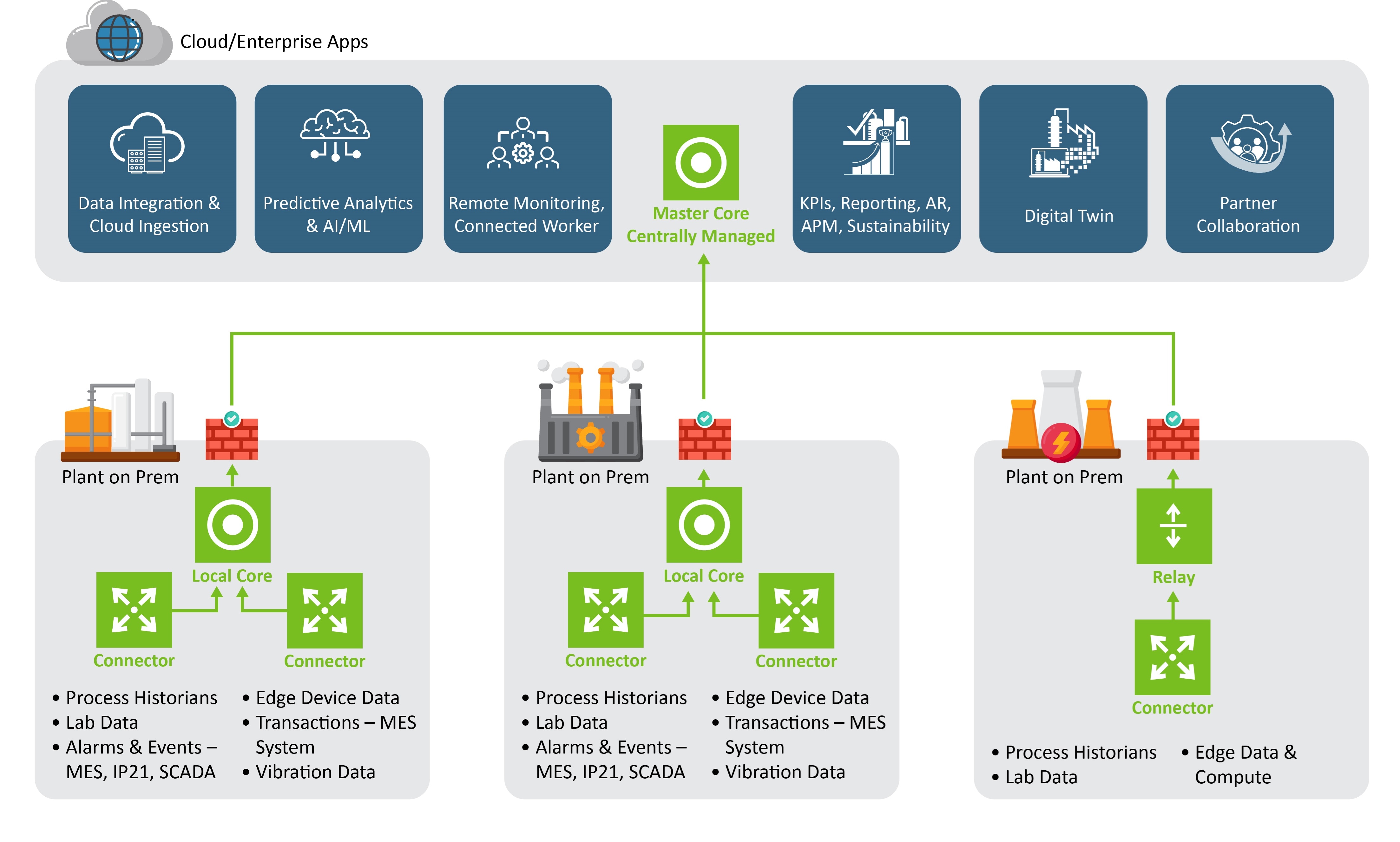

Effortless Scalability for Global Industrial Data Management

- Enables efficient management of large industrial data scopes across global operations

- Ensures reliable performance as data needs grow—ideal for expanding systems across multiple sites or networks

- Supports seamless infrastructure expansion, adapting to increasing data demands without compromising efficiency

- Designed for businesses requiring large scale, robust data integration and analysis

Fortified Data Protection, Comprehensive Security

- Access Controls: Granular user permissions and authentication mechanisms

- Encryption: Data encryption at rest and in transit to safeguard sensitive information

- Compliance: Adheres to industry security standards and regulations

- Audit Trails: Detailed logs for monitoring and reviewing data access and system changes