Maximize Safety, Sustainability and Productivity by Turning Unplanned Downtime Into Planned Downtime

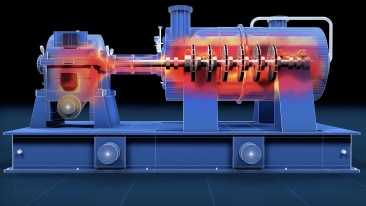

What if you could actually plan for downtime? Using advances in machine learning and predictive analytics, it's now possible to predict which pieces of equipment are going to fail, and when, and then perform repairs as part of a managed shutdown.

Download this paper to learn how asset performance management is delivering significant return on investment by reducing unplanned downtime, while improving your ability to maintain safe operations and meet environmental goals.