V10: Sequence With Staggered Analysis

Staggered Analysis is now available with BLOWDOWNTM Technology in Aspen HYSYS. More accurately validate disposal system adequacy and determine the best opening sequences for blowdown valves that discharge to the same disposal system. Save costs by avoiding overdesigns or replacements to accommodate greater capacities.

V9: Reduce Risk with Sulfur Recovery Modeling

Predict sulfur emissions, maintain reliable operations and adhere to regulations by modeling the full gas plant with Sulsim™ Sulfur Recovery in Aspen HYSYS. More efficiently optimize the entire plant and evaluate strategic studies, feed changes and process configuration changes.

V9: Improvements to Acid Gas Cleaning

Acid Gas Cleaning in Aspen HYSYS has been enhanced to include a new property package for liquid treating to simulate acid gas extraction from NGLs and LNG. Additionally, identify any hydraulic issues with column design and rating with Column Analysis in Aspen HYSYS.

V9: Additional Improvements to Aspen HYSYS

Use the Mercury Stream Utility in Aspen HYSYS to calculate the mass flow of free mercury. Prevent damage to equipment and the poisoning of catalysts. Adding to the centrifugal and reciprocating compressor models, the screw compressor model allows you to calculate volumetric efficiency and use Aspen HYSYS Dynamics to look at start-up and shut-down.

.jpg)

Push the limits of performance with Aspen HYSYS.

Visit our NEW Aspen HYSYS Resource Center! As the leading innovator in process simulation software for more than 30 years, Aspen HYSYS provides greater accuracy, integration and ongoing innovation than any other process simulation tool for the energy industry. This resource center will help new and experienced users discover the full power of Aspen HYSYS.

V8.8: Methanol Partitioning with Cubic-Plus-Association Equation of State

With the addition of the Cubic-Plus-Association (CPA) Equation of State (EOS), you can achieve improved accuracy when performing methanol partitioning within Aspen HYSYS to help you meet your environmental compliance goals. CPA is also compatible with the enhanced Hydrate Formation utility, which now computes the amount of inhibitor needed for hydrate suppression.

V8.8: Rigorously Model All of Your Refinery Reactors

With the addition of the new Naphtha Hydrotreating, CatGas Hydrotreating and Alkylation reactor models, Aspen HYSYS Petroleum Refining now has a complete suite of rigorous kinetic models to support all major refinery processes. Accurately model all complex refining processes in the easy-to-use Aspen HYSYS environment. Make better planning and optimization decisions with the support of calibrated models.

V8.8: Improvements to Activated Analysis

Activated Analysis has been significantly improved for better performance, speed, and discoverability to promote a more efficient workflow. Activated Analysis fully integrates energy optimization, exchanger design & rating, and cost estimation tools, used by experts, with the process model using industry standard defaults or customizable templates.

Activated Economics and Energy are available with aspenONE V8.0. Activated EDR is available with aspenONE V8.4.

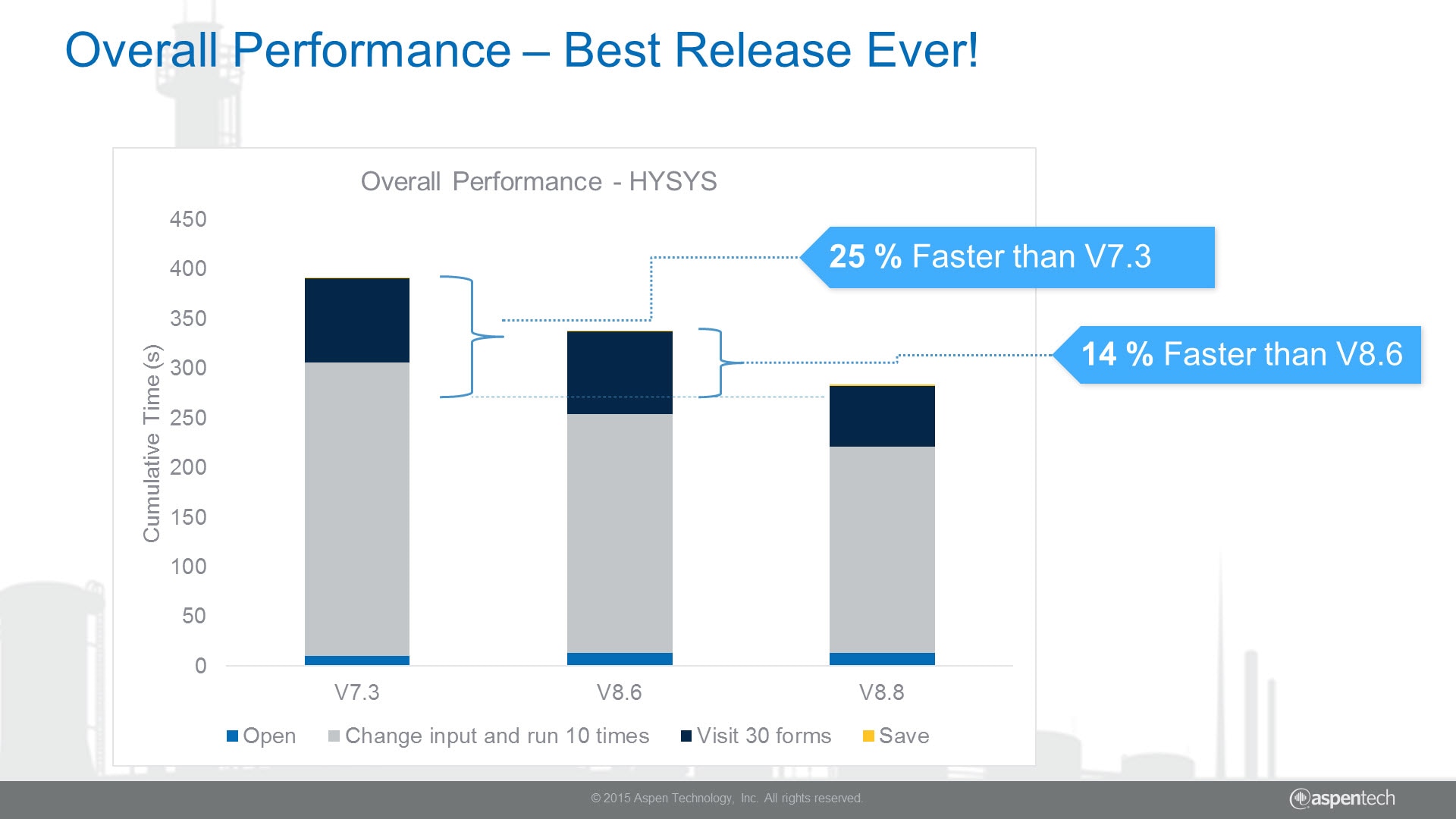

V8.8: Improved Performance

With each release, aspenONE® performance is thoroughly tested to make sure new innovations haven’t impacted its performance. Twenty-five different cases covering virtually all unit operations of varying size and complexity are used to test the open times and go through a process engineer’s workflow. In the V8.8 release, special attention was paid to improving performance. We tested cases covering Aspen HYSYS, Upstream, and Refining, including Dynamic simulation, comparing version 7.3 cases to V8.8, V8.6, and V8.4cp3.

V8.6: Activated Dynamics for Compressor Surge Analysis

Activated Dynamics in Aspen HYSYS enables users to perform easy dynamic process simulation by quickly creating dynamic models for surge simulation, encapsulating expert knowledge and enabling faster transition from steady-state to dynamic modeling. Analyze dynamic behavior and easily troubleshoot potential operational problems.

Starting from V8.8, two and three stage compressor templates are available.

Available starting with aspenONE V8.6.

V8.8: Enhancements to Relief Sizing in Aspen HYSYS

First introduced

in Aspen HYSYS V8.3, the relief sizing capability means you have access to a

powerful pressure relief sizing tool within Aspen HYSYS. This capability allows

you to analyze, size, and document pressure safety valves (PSVs) right in the

simulation. In later versions, additional features have been added, including

automatic import of sized PSVs to Aspen Flare System Analyzer, storage tank

protection, rupture disk sizing, multivalve analysis, and more rigorous fire

scenario calculations. With the introduction of V8.8, rigorous calculations

are now extended to tube rupture and control valve failure scenarios.

Newly available detailed validation report can be accessed through

support.aspentech.com

PSV sizing functionality is available in Aspen HYSYS V8.3 and has been enhanced for V8.4 and V8.6.

V10: Calibrate Models With Plant Data

With the new activated online modeling feature directly within Aspen HYSYS, you can import and condition data, map variables with tags, run, connect and validate models with plant historian data, and analyze the results.

V8.6: Enhanced Acid Gas Cleaning functionality

Acid Gas Cleaning allows you to look at an entire gas plant model or refining process to further optimize design and performance.Rigorous rate-based calculations and special property packages deliver accuracy and predictive results to acid gas absorption processes using amine and DEPG solvents. Take into account ammonia contamination, and model gas treating processes that are usingphosphoric acidas a stripping promoter.

DEPG Solvent: http://www.aspentech.com/wp-acid-gas-validation-DEPG-NOV14/

Acid Gas Cleaning functionality in Aspen HYSYS is available starting with aspenONE V8.3.

Acid Gas Physical Solvents property package is available starting with aspenONE V8.6.

V8.6: E-Learning in Aspen HYSYS®

AspenTech currently offers Online Training to help you get up to speed faster with our products. Now with E-Learning in Aspen HYSYS®, you have access to carefully curated learning content organized by topics. Find relevant E-Learning groups with a plethora of helpful material, including CBTs, Jump Start Guides, example models, video tutorials, blogs from the AspenTech Community, and more.

V8.4: New reactor models and Assay Management in Aspen HYSYS® Petroleum Refining

Aspen

HYSYS Petroleum Refining now offers the new Assay Management feature and

introduces the new Delayed Coker and Visbreaker reactor models into the

refinery reactor suite. Enhance heavy crude modeling with improved assay

characterization for complex crudes and reactor models calibrated to match

your plant.

V8.4: Activated Exchanger Design and Rating

V10: More Accuracy for Dehydration With CPA

Dehydration involving TEG, MEG and DEG can be modeled in Aspen HYSYS with the Cubic Plus Association (CPA) Equation of State (EOS) property package. CPA EOS is recommended over the glycol property package that’s available in Aspen HYSYS V9 and earlier.

V10: Predict Sulsim Degasser Performance

With the addition of the degasser model, Aspen HYSYS can now model the solubility properties of H2S in liquid sulfur. The predicted concentration of the H2S content that leaves the condenser is now available as part of the stream. The degasser unit operations report on liquid sulfur outlet density, thermal conductivity, viscosity, heat capacity, and surface tension.

V10: Improve CDU Modeling Using EO

Aspen HYSYS V10 offers an improved “equation-oriented (EO) solver” to model complex crude distillation units with nested recycle loops and integrated heat exchanger networks. Data reconciliation and process optimization can be completed significantly faster using EO technology.

V10: New Solvents for Acid Gas Cleaning

Acid Gas Cleaning in Aspen HYSYS has been improved with new solvents (Sulfolane + MDEA + Pyrazine, MDEA + MEA +DEA, and any two mixed amines), and new components (heavy hydrocarbons, heavy mercaptans). Models for H3PO4 on H2S absorption and regeneration were improved, as well as an improvement when predicting regenerator duty, particularly in the MDEA + PZ amine blend.

V9: Refinery Planning Models are Easier to Update

Save significant time and effort when updating refinery planning models, with substantial improvements in the Microsoft® Excel interface for process simulation flowsheets and case study tools that’s available in Aspen HYSYS.

V9: Revolutionize your BLOWDOWN Analysis

BLOWDOWN, the industry’s proven depressurization technology developed by Doctor Graham Saville and Professor Stephen Richardson, is now available in Aspen HYSYS! With this depressurization tool you can design an orifice for pool fire scenarios, select materials of construction for cold case systems and assess risk to the facility based on peak pressures reached in the system during overpressure.

V9: Get a More Detailed View of Your Distillation Columns

Column Analysis in Aspen HYSYS allows you to view the whole column, identify any hydraulic issues, understand the operating range, and communicate your findings. See how modifications in packing and trays change the hydraulic plots and the operating range of the columns. Calculate costs as you make changes.