Optimize Flow and Prevent Equipment Damage

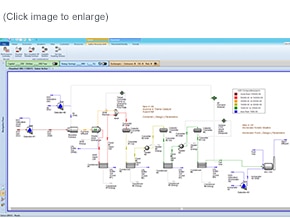

Consider hydraulics for single pipelines or entire gas gathering networks using Aspen HYSYS, Aspen HYSYS Upstream and Aspen HYSYS Upstream Dynamics. Implement flow assurance and perform dynamic pigging simulation for complete support of pipeline maintenance operations. Integrate pipelines with your gas plant model to optimize operations.

Meet Acid Gas Regulations Consistently and Reliably

Acid Gas Cleaning in Aspen HYSYS uses rigorous rate-based calculations and specialized property packages to deliver unprecedented accuracy and predictive results. Model a large set of amine solvents, a DEPG physical solvent, and acid gas extraction with liquid treating. Track key contaminants, sulfur species, stripping agents, and heat stable salts.

Prevent Shutdowns with Sulfur Recovery Modeling

Predict sulfur emissions, maintain reliable operations, prevent disturbances and adhere to regulations by modeling the full gas plant with Sulsim™ Sulfur Recovery in Aspen HYSYS. Use 33 unit operations and a specialized property package to model your unit. More efficiently optimize the entire plant, and evaluate strategic studies, feed changes and process configuration changes.

Available starting with Aspen HYSYS V9.

Optimize Dehydration Units

Aspen HYSYS is a reliable product for modeling systems with glycol, including TEG, making it ideal to optimize natural gas dehydration. Founded on the Twu-Sim-Tassone (TST) equation-of-state, the Aspen HYSYS glycol property package provides reliable methods for phase equilibrium, surface tension prediction and liquid density prediction.

Reduce NGL Recovery and Fractionation Costs

Heat exchanger design is important for effective separation process schemes in new and existing NGL recovery facilities. Use Aspen HYSYS to design NGL recovery and test multiple exchanger types during conceptual design for optimal performance. Call upon rigorous heat exchanger models from within Aspen HYSYS, including Aspen Shell and Tube and Aspen Plate Fin.

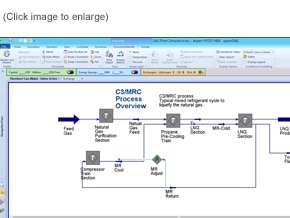

Minimize Risks in LNG Facilities

Compressor and heat exchanger design and rating are essential for optimized natural gas liquefaction. Troubleshoot and prevent potential operational problems with compressor surge analysis in Aspen HYSYS Dynamics. Be certain that the most accurate thermodynamic properties are being used with access to Aspen Properties and GERG2008 for natural gas mixtures.

Meet Environmental Regulations

Ensure regulatory compliance and facilitate plant permit acquisition using gas processing software. With the Cubic-Plus-Association (CPA) equation-of-state , you can achieve improved accuracy when performing methanol partitioning within Aspen HYSYS. Additionally, predict the accumulation of mercury in gathering systems, gas plants and refineries with Mercury Partitioning capabilities in Aspen HYSYS.

Improve Accuracy in Capital Cost Estimates

Aspen Capital Cost Estimator (ACCE) reduces the time for decisions by 20-30% and delivers estimates within 5-10% of the actual. ACCE also helps determine project viability and the most economical production route when designing upstream and midstream processes, where you can use data from a gas plant model for cost estimation.

Push the limits of asset performance.

Visit our NEW Aspen HYSYS Resource Center! Aspen HYSYS provides the most powerful process modeling capability, helping companies operate as profitably as possible within the given limits. This resource center will help new and experienced engineers discover the full power of Aspen HYSYS, the most trusted process modeling software for the energy industry.