Aspen Fired Heater®

Design and explore various fired heater configurations. Ensure optimal performance of exchangers and troubleshoot operations with sophisticated, flexible and easy to use modeling capabilities.

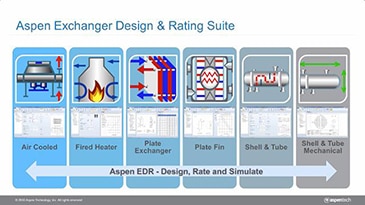

Part of AspenTech’s Comprehensive and Rigorous HX Modeling Solution

Improve Production and Efficiency

Maximize throughput and energy efficiency with insight into process conditions using sophisticated and flexible modeling capabilities. Model a wide range of heater configurations with full integration of firebox / convection heat transfer sections combined with draft calculations.

Monitor and Troubleshoot Operational Performance

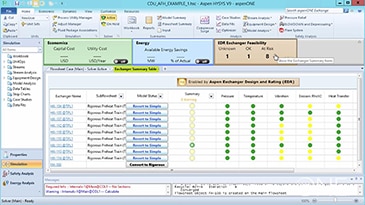

Instantly view the impact of process changes on heat exchanger operational performance by easily importing designs to Aspen HYSYS®.

Designs You Can Trust

Proven modeling technology based on proprietary theoretical models and correlations backed by over 40 years of experimental study. Easily validate design with in-product access to source methods, models and data.