Aspen Exchanger Design & Rating (EDR)™

Optimize CAPEX and OPEX by modeling heat exchangers within the larger process with rigorous HX models and seamless data flow across disciplines.

Heat Exchanger Design Software with Comprehensive Set of Rigorous HX Models

Activated Exchanger Design and Rating

Up-to-Date Documentation

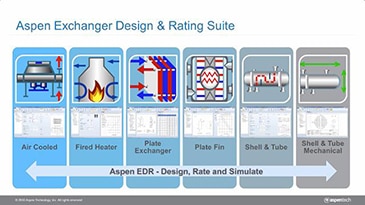

All Major HX Types

Vast Physical Property Database

Introducing aspenONE Engineering deployment in the cloud: Access the latest software anytime, anywhere

aspenONE Engineering software is now available for cloud deployment! aspenONE Engineering deployment in the cloud accelerates deployment and lowers the total cost of ownership for IT departments and allows user access to the latest aspenONE Engineering innovations anytime, anywhere, through a web browser.

Related Content

Learn how AspenTech Solutions Helped Fix Operational Issues with a Major Refiner's CDU

Learn how a major Middle East Refinery used AspenTech solutions to address operational issues with their crude distillation unit (CDU). This video highlights how the detailed hydraulic analysis capabi...

Video

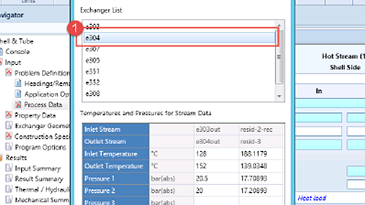

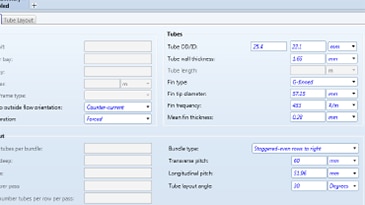

Jump Start Guide to using Aspen Shell & Tube Exchanger

Aspen Exchanger Design and Rating (EDR) enables you to find the optimal design for your heat exchanger needs based on cost. The seamless integration between the thermal and mechanical design tools of ...

Self-Guided Demo

Design Air Coolers for Crude Distillation Unit

Step by step instructions on how to design air cooled condensers for a refinery application using Aspen EDR and Aspen HYSYS.

Self-Guided Demo

Petrofac Improves Process Design Accuracy by Debottlenecking Gas Processes Increasing Capacity by 20%

Download this case study to learn how Petrofac used Aspen HYSYS with Activated EDR models to optimize heat exchanger selection and configuration for a gas production client. This solution achieved the...

Case Study

European Engineering Company Saves $400,000 USD on CAPEX Using Performance Engineering

Discover how PETROLTERV saved significant CAPEX on a revamp project due to greater design accuracy enabled by the integrated aspenONE Engineering suite of products. Due to efficiencies gained from usi...

Case Study

Activated EDR in Aspen HYSYS

Learn how to save on energy, CAPEX and OPEX by improving the fidelity of your process simulation flowsheets using rigorous heat exchanger models. Now it is easier than ever to generate rigorous heat e...

Video

Aspen Exchanger Design & Rating Family

Heat exchangers can comprise up to 30% of capital equipment and impact 90% of the energy used in a process plant.

BrochureAspen How-To

Looking for quick demonstrations on using AspenTech products to solve your engineering and operations challenges? Browse this compilation of bite-sized videos produced by AspenTech experts covering all our major solutions.

Aspen Self-Paced eLearning

Find on-demand training for applying AspenTech products to your complex process engineering and operational problems. Our comprehensive eLearning courses, created by AspenTech experts, offer self-guided learning paths for all our major solutions.

Aspen Expert-Led Training

We offer comprehensive libraries of classroom and virtual expert-led training courses for our process engineering and operational solutions. All courses are created and produced by AspenTech experts.

Competency Development

Designed to meet industry standards and company-specific goals, AspenTech’s competency development program helps you build and sustain in-house expertise by leveraging flexible training options—including certification—and measuring organizational competency against industry benchmarks.