Aspen HYSYS Petroleum Refining™

Enable sustainable and profitable refinery operations by layering powerful refining simulation capabilities onto the Aspen HYSYS® process simulator.

Improve Refinery Margins with Accurate Prediction of Product Yields and Properties

Refinery-wide Process Modeling

Comprehensive and Rigorous Reactor Modeling

Improve Refinery Planning and Process Optimization

Related Content

Hyundai Oilbank Uncovers $36M USD/Year Using Aspen HYSYS®

Learn how Hyundai Oilbank optimized FCC operations using Aspen HYSYS, significantly improving the units planning accuracy.

Micro Case Study

Industrial AI in Action: Improve Reactor Operations with Unprecedented Simulation Accuracy

Reactor operations continue to be critical for today’s refineries, but reactor simulation solutions have traditionally been difficult to use and maintain. The problem is magnified as experienced engin...

On-Demand Webinar

Petro Rabigh Uses Aspen Hybrid Models™ to Improve Margin and Reduce Operational Risk

Petro Rabigh wanted to improve margins for refinery products, to do so, they needed to identify the most optimal production yields and qualities of their refinery and petrochemical products.

Case Study

Saudi Aramco Increases Refinery Capacity by 100,000 Barrels/Day Using Plant Digital Twin

Learn how Saudi Aramco used Aspen HYSYS to analyze feasibility of refinery reconfiguration plans by developing plant digital twins of multiple units. The new reconfiguration plan projects a 100,000 ba...

Case Study

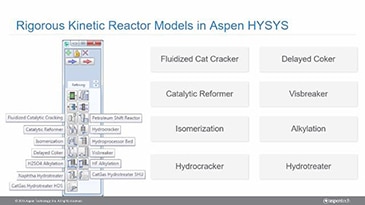

Learn How You Can Have a Kinetic Model of Any Major Refinery Reactor in Aspen HYSYS

Learn how you can use Aspen HYSYS to develop a rigorous model of any major refinery reactor. Aspen HYSYS offers a complete suite of all major refinery reactor units.

Video

Learn How to Accurately Predict Impact of Operational Changes on Refinery Profit

See how engineers can develop and use a refinery-wide process model in Aspen HYSYS to accurately predict the impact of operational improvements on the refinery’s profit.

Video

Webinar with Viva Energy and Anukoolan: Optimizing CDU Operations with Equation-Based Digital Twins in Aspen HYSYS®

Today, enterprises are challenged with ensuring quick business transitions to keep up with changing demands in a volatile and uncertain markets.

On-Demand Webinar