Activated Analysis in Aspen HYSYS® and Aspen Plus®

Optimize your design by evaluating process alternatives analyzing their cost, energy usage, emissions and equipment design from the same environment.

Reduce Engineering Time and Cost with Simultaneous Multi-Disciplinary Analysis

Economic Analysis

Energy Analysis

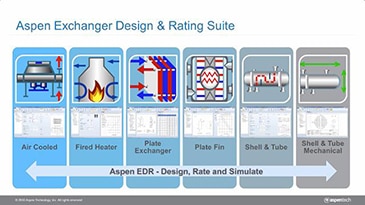

Heat Exchanger Design and Rating

Emissions Dashboard

Related Content

Sustainability Takes Center Stage

Sustainability is no longer an option—it’s an imperative. Awareness and alarm about the impact of human activity on the environment has begun to shift buying and investment behavior around the world. ...

Executive Brief

Solution Demonstration: How to Accelerate Feasibility & Delivery of Capital Projects

This video showcases the streamlined workflow enabled by AspenTech Concurrent Engineering applied to a carbon capture project. The workflow enables the creation of state-of-the-art process simulation,...

Video

Make Informed Process Design Decisions Using Activated Economics

How do you consider capital and operating expenses while developing process designs? With Activated Economics, process engineers can quickly and accurately identify the economic impact of design decis...

On-Demand Webinar

Developing an Integrated Sustainability Business Plan

To remain competitive, companies must develop new levels of operational excellence, gaining agility, flexibility and insight via digitalization.

Blog

Activated EDR in Aspen HYSYS

Learn how to save on energy, CAPEX and OPEX by improving the fidelity of your process simulation flowsheets using rigorous heat exchanger models. Now it is easier than ever to generate rigorous heat e...

Video

European Engineering Company Saves $400,000 USD on CAPEX Using Performance Engineering

Discover how PETROLTERV saved significant CAPEX on a revamp project due to greater design accuracy enabled by the integrated aspenONE Engineering suite of products. Due to efficiencies gained from usi...

Case Study

LG Chem Significantly Increases Plant Capacity and Reduces Energy Usage

LG Chem increases capacity by 15% and saves energy through heat integration using Aspen Plus®, Aspen Energy Analyzer™ and Aspen Exchanger Design and Rating™.

Case Study