Streamline exchanger design for faster project execution.

Activated EDR evaluates hundreds of design geometries for the specified process requirements. Utilize rigorous heat exchanger models for accurate thermal & hydraulic modeling in simulation and to evaluate process design feasibility with Activated Economics. Preliminary exchanger designs can easily be exported for thermal & mechanical optimization by specialists—increasing engineering efficiency and encouraging cross functional collaboration.

Identify equipment bottlenecks to increase plant capacity.

Heat exchangers are often bottlenecks in process operations. With Activated EDR, users can easily incorporate rigorous heat exchanger models to troubleshoot exchanger performance under the specified operating conditions. Easily identify equipment constraints and explore strategies to optimize process performance.

Optimize heat exchanger designs to reduce capital and operating costs.

Activated Exchanger Design & Rating works with Activated Energy and Activated Economics in both Aspen Plus and Aspen HYSYS. You can size an exchanger, obtain a relative cost estimate, and then perform pinch analysis—all without leaving the simulator.

Minimize the risk of costly operational problems in heat exchangers.

With Activated EDR, you can instantly see the impact of design decisions and troubleshoot exchanger performance. You can easily identify and monitor critical performance issues such as excessive operating temperature & pressure, erosion or vibration risks, and more—allowing you to readily identify exchangers that constitute operational constraints.

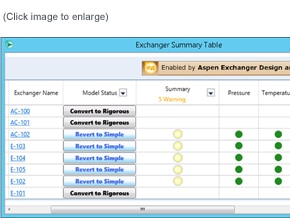

Manage all heat exchangers from one table.

With Activated EDR, you can view all heat exchangers in a process from one table—regardless of their location in flowsheets & subflowsheets. From one table, you can easily convert from simple models to rigorous heat exchanger models and back and view operational risks that may arise in process design—making it easier to troubleshoot exchanger performance before costly problems arise.